Espace réservé

Boite à outils

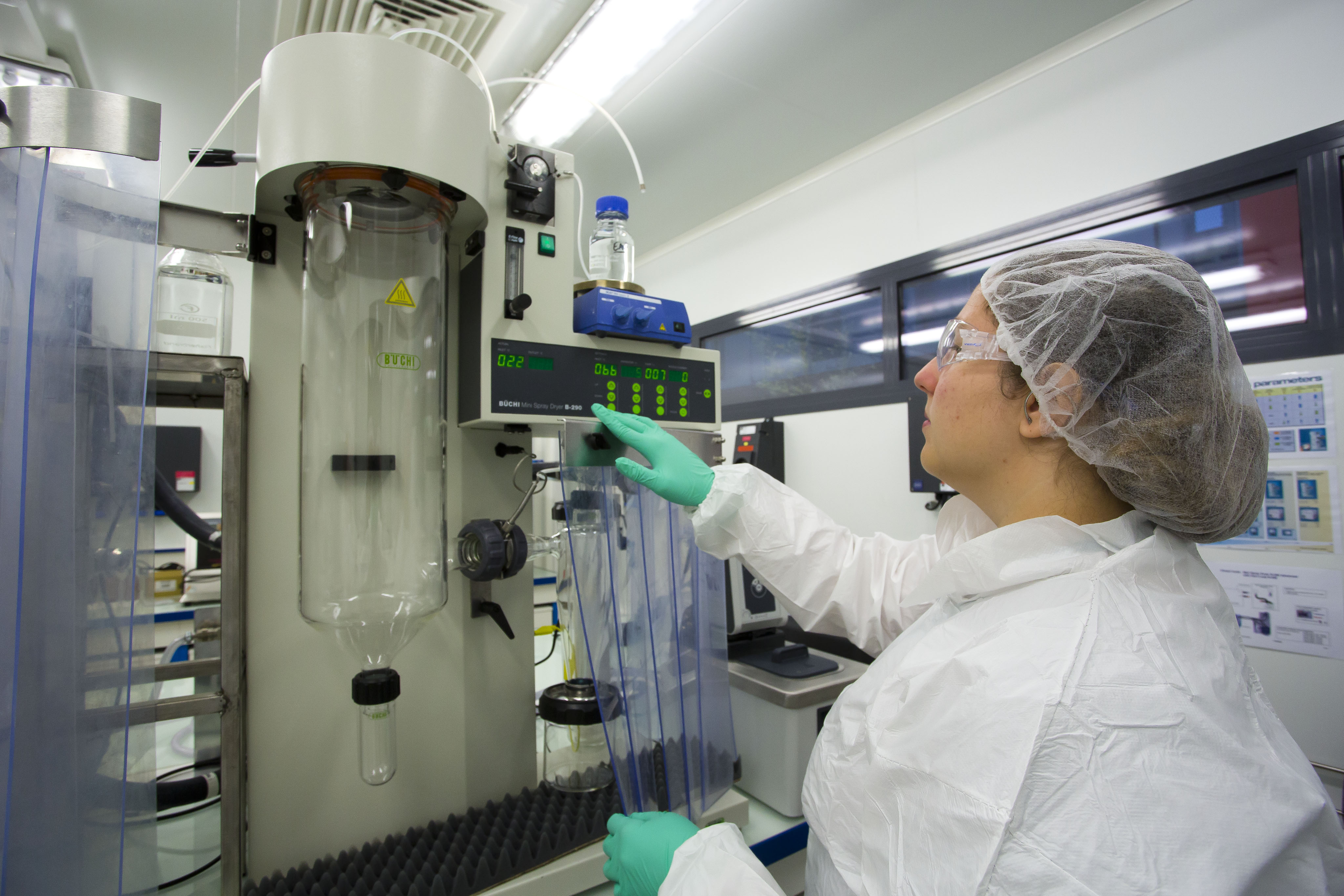

Spray dryer Buchi B290

Spray Drying technology

The Gala platform is equipped to a spray-drying at laboratory scale. The system can spray aqueous solution, dispersions and emulsions and to dry it with an air flow or with inert gaz (nitrogen) in order to generate dry powder.

With this equipment, different nozzle sizes are available to disperse the liquide into fine droplets, which are dried quickly and gently in the drying chamber. The generated powder is trained by the aspiration into the cyclone which separates the particles to the gaz.

For organic solvents, and explosive materials, the spray-dryer operates as a closed-loop system, with a condensation system for solvents vapour and a security system for gas detection).

Technical specifications:

- The Mini Spray Dryer B-290, en version advanced, equipped either aqueous solutions or organic solvents. The maximal evaporating capacity is 1.0 liter/h. The maximal inlet temperature is 220°C. The Mini Spray Drier allow to dry small volumes of solutions, from 30 millilitres to few litres.

- An Inert Loop B-295 is associated to the Spray Drier to handle organic solvents safely.

- A Dehumidifier B-296 is an accessory to condition the drying air or to work continuously with water and organic solvent mixtures.

- Two type of cyclone can be used: a standard cyclone and a high-performance cyclone to achieve higher yields.

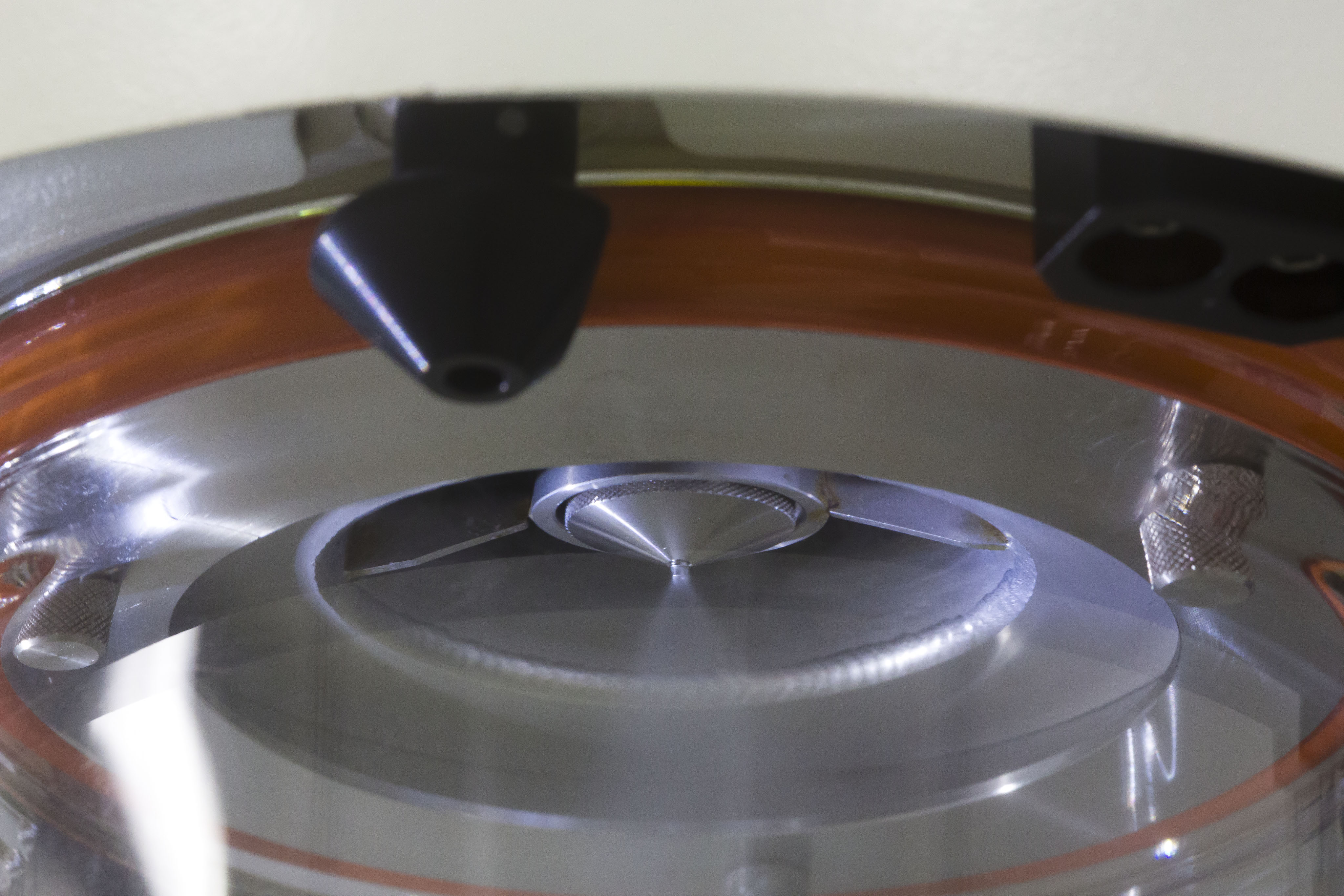

- A two-fluid nozzle sprays the liquid into the drying chamber. Different sizes are available to modify the powder morphology (nozzle exchange sets of 0.5mm, 0.7mm, 1.4mm and 2.0 mm). In general, the particle diameter range is from 1 to 25 µm.

- A three-fluid nozzle is available to spray two independent sample feeds at the same time. It allows to spray dry immiscible samples for micro encapsulation applications.

This equipment is available for R&D projects with industrial specifications in a wide range of fields (pharmaceutical, cosmetic, food, feed, fonctional materials and nanomaterials).

Spray nozzle in operation (three-fluid nozzle with a 1.4 mm size).